OEE+

The ‘Real Time OEE Solution’

OEEPlus is OEE but with added real time data capture (‘Plus’). Real time means the data is captured at its origin; in Manufacturing. The OEEPlus software is designed to connect to a machine either via OPC (Object Link Embedding for Process Control) or more commonly, using a dedicated OEEPlus data capture Hub. The hub provides a universal interface between the machine and the software by reducing the connections to a few simple digital inputs and outputs. This makes it compatible with any equipment regardless of age or control system type: OEEPlus can therefore be used on any machine.

Via the hub, OEEPlus can detect machine stops and starts, event types and log good or waste product count. The high speed inputs on the hub guarantee that OEEPlus will not miss product counts even on high speed packaging lines.

Empowering the Operator

OEEPlus aims to capture 100% accurate data and it achieves this by empowering the machine or plant operator. Even the most sophisticated control system cannot detect all sources of downtime and the contribution of the machine operator is vital. OEEPlus makes it easy for the operator to interact with the machine; the user interface has been carefully designed so that operators of all technical competencies can use it, with 99% of all operator functions being touch screen button presses that require no keyboard skills.

Infinitely Configurable and Flexible

OEEPlus puts you in control. You configure the works orders, products and events types. The downtime events are organised hierarchically and the depth of the tree is limitless, making it possible to accurately group the sources of downtime no matter how many downtime reasons exist.

Standalone or Enterprise Solution

OEEPlus has been designed to work as a standalone terminal or as part of an enterprise solution by keeping copies of both the configuration and runtime information locally and remotely. When running standalone the data store is usually a plug in memory device such a USB memory stick. This stick containing the data store can then be removed and placed in an office based machine for configuration, runtime data reporting and exporting. In enterprise mode, the runtime information is posted to a remote web server where reports and analysis can be run across multiple machines and locations.

OEEPlus Enterprise will even host your data for you so there is no need to set up expensive server hardware and network infrastructure. Providing the terminal has access to the Internet then the data can be transmitted securely to one of the many OEEPlus servers. Authorised users can then access the data, perform analysis and run reports via a standard Internet browser in ‘Real Time’ from any computer, anywhere in the world.

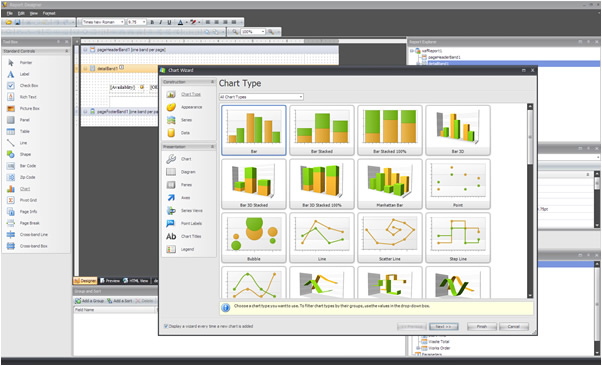

Analysis and Report Builder

OEEPlus has a vast array of standard production, downtime and minor stop reports. But OEEPlus has a unique built in Analysis and Report Builder tool that helps customers to produce their own reports and data views. The Analysis module provides PivotGrid and Charting functions that make it simple to aggregate sometimes complex data and present it; in easy to understand grids and charts. The Reporting module produces an output that can be easily printed or exported into Excel, HTML or PDF formats.

Complex Security

OEEPlus supports a complex security model where different users, roles and permissions can be configured. A simple operator login is provided so that in ‘Runtime’ mode no keyboard is required and it can all be driven from a touch screen. The runtime interface is designed for the factory floor, keeping it simple ensures its always available.

Hardware and Pricing Options

As well as the hub, OEEPlus has some ready built ruggedized touch screen terminals designed and ready to be deployed in manufacturing. The terminals come in a number of different screen sizes and are preloaded with the OEEPlus software.