The Project

Unilever SCADA

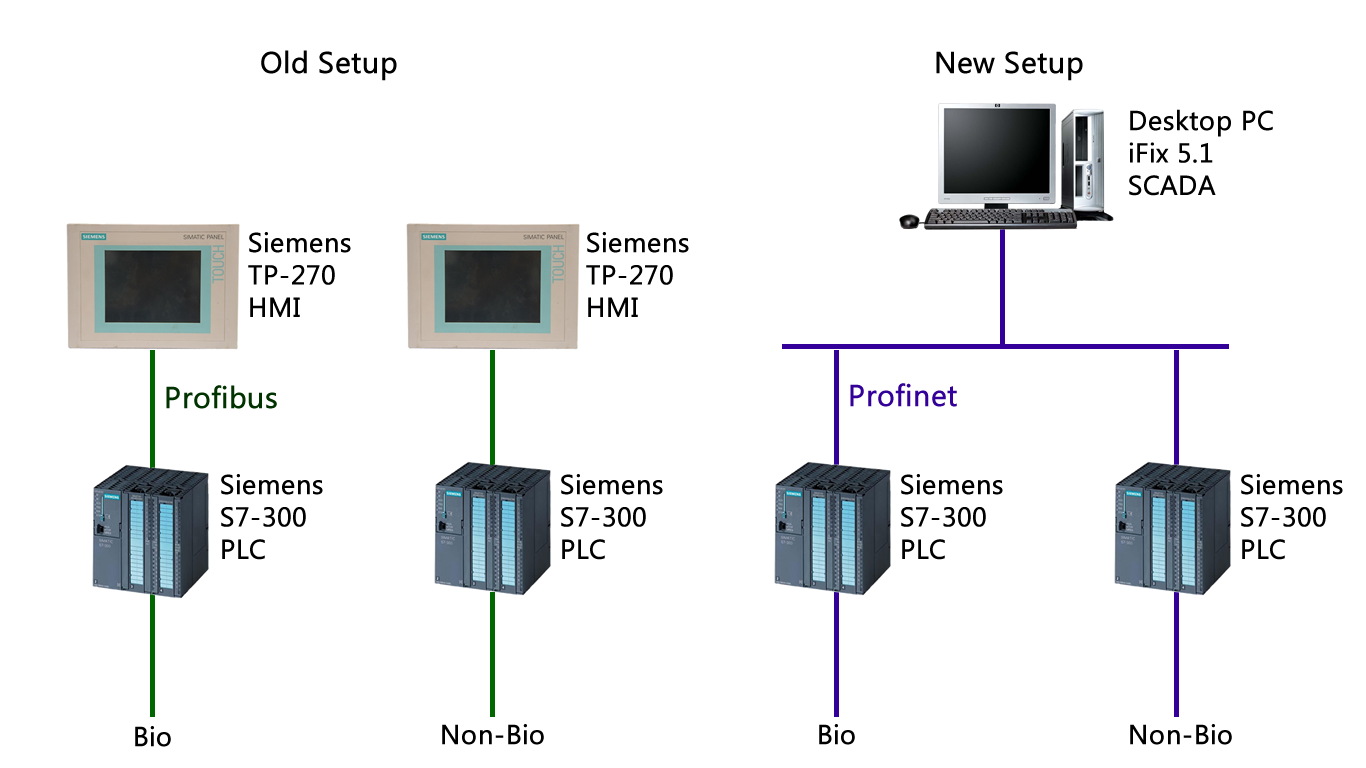

Unilever approached us with a project to upgrade their two identical Liquid Tab manufacturing facilities that each had their own Human Machine Interfaces (HMI) to a single SCADA system to manage both plants. The existing HMI was a Siemens TP270 which is now obsolete, and as part of the upgrade process the communication was to be migrated from Profibus to Profinet. Profinet is Profibus over Ethernet and so operates at a much higher communication rate which would mean update times on scada variables would be significantly improved. Having a PC with it's potential storage capabilities would offer significant further benefits for data logging.

Manual controls

The original manual screen was a list of devices with open/close buttons and just a number for each device, no relative position or other information was given regarding these devices, this caused problems such as a plant operator unfamiliar with with the controls not knowing what each device does. The new scada system has manual device control pop-ups on the plant overview screens, meaning that the device position will be clear to any user so the plant can be controlled effectively.

Historical Trending

Process variables can be logged such as tank levels, tempratures, flow rates, etc. This data is called time series data and is presented in a line graph, this allows operators to view production history and current status, variables and efficiency can also be found.

Build Process

The new SCADA was to be built in GE Fanuc iFix 5.1, the old HMI screens were unable to be used so a printout of each screen was provided, however the existing 'process tag' database was accessible. All the screens had to be re-drawn and re-tagged various updates and fixes were added in the new SCADA system such as the interface on the control screens was given a more 'modern' Windows 8 look. The manual valve control page was removed and the valves could be operated from the plant overview screens to make clear to the operator which valve does which function.